Aqua MegaDisk® Cloth Media Filter

The Next Evolution in High-Capacity Tertiary Filtration

As wastewater treatment standards continue to tighten, many facilities face increasing pressure to deliver clearer effluent, handle peak hydraulic loads, and reduce operational complexity – all within the same limited footprint. Traditional tertiary filtration systems often require large basins, heavy maintenance, and high energy inputs, making upgrades challenging for both municipal and industrial plants.

The Aqua MegaDisk® is engineered to overcome these limitations. Building on the proven performance of the original AquaDisk® technology, Aqua MegaDisk® delivers larger filtration capacity, fewer mechanical components, and the smallest footprint available. With oversized cloth media disks and highly efficient solids capture, the system provides advanced tertiary treatment while drastically reducing space and energy requirements.

How Does It Work?

The Aqua MegaDisk® filtration system uses a simple yet robust operating sequence that ensures continuous, uninterrupted tertiary treatment – even in variable loading conditions.

Filtration Mode

Incoming wastewater flows by gravity into the influent channel, where the fully submerged cloth media disks begin the filtration process. As water moves through the depth of the pile cloth:

- Solids are trapped and stored within the cloth media

- The filtrate collects inside the hollow disk core

- Clean water is transferred to the effluent channel by gravity

- Heavy particles naturally settle to the tank bottom

This depth-filtration mechanism provides exceptional solids capture while maintaining high hydraulic capacity.

Backwash Mode

To sustain peak filtration efficiency, the system automatically initiates backwashing based on rising water level or timing logic.

During backwash:

- The disks rotate slowly while the system remains in full filtration mode

- Vacuum shoes press directly against the cloth surface

- Accumulated solids are lifted off the media using vacuum pressure

- The backwash/solids pump coveys wash water to the headworks

This non-interruptive cleaning cycle keeps the system continuously online and reduces mechanical wear.

Solid Wasting Mode

Settled solids at the bottom of the tank are periodically removed to maintain optimal hydraulic performance.

- The backwash/solids pump applies suction to the solids manifold

- Collected sludge is withdrawn and conveyed to existing sludge handling processes

This ensures efficient solids management without manual intervention.

Proven Features & Benefits

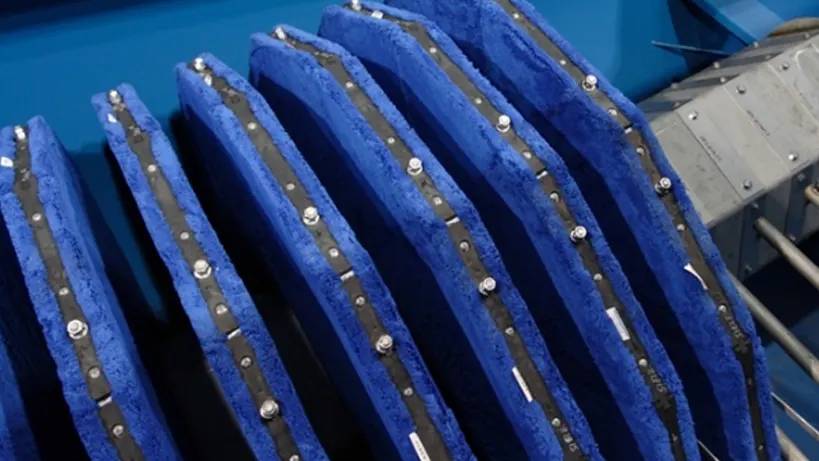

Advanced Cloth Media Technology

Exclusive OptiFiber® pile cloth media ensures high solids capture and superior effluent quality – ideal for stringent tertiary standards.

Largest Disk Size in the Industry

Each disk measures approximately 10 feet in diameter, drastically increasing filtration capacity while minimizing equipment count.

Compact, High-Throughput Design

With upto 24 disks in a single unit, Aqua MegaDisk® can treat flows up to 24 MGD, reducing the need for multiple filter trains.

Low Energy, Low Maintenance

Disks remain stationary except during backwash, resulting in lower power consumption and fewer mechanical wear components.

Flexible Construction Options

Available in painted steel, stainless steel, or concrete tank configurations to match plant requirements.

Smaller Footprint, Lower Costs

Higher loading rates and fewer moving parts lead to reduced capital cost, reduced footprint, and optimal lifecycle efficiency.

Why Facilities Choose Aqua MegaDisk®

The Aqua MegaDisk® Cloth Media Filter is trusted by utilities and industries requiring dependable tertiary treatment because it delivers:

- Consistent regulatory compliance with exceptional solids and turbidity removal

- Operational efficiency, with reduced mechanical components and energy use

- Lower long-term O&M costs due to simplified maintenance and fewer pumps/valves

- High hydraulic capacity in minimal space- ideal for retrofits or expansion constrained facilities

Engineered for real-world conditions, Aqua MegaDisk® provides stable, predictable filtration performance even under challenging flow and loading scenarios.

Upgrade Your Tertiary Treatment Performance

Aging filters or large-footprint sand systems can limit a plant’s ability to meet modern effluent standards. The Aqua MegaDisk® Cloth Filter offers a powerful upgrade path – delivering higher clarity, reduced maintenance, and long-term sustainability.

Whether for municipal polishing, industrial tertiary treatment, or retrofit applications, Aqua MegaDisk® enhances system stability while minimizing operational challenges.

AquaDisk® Cloth Media Filter

The Original Standard in Tertiary Wastewater Filtration

For decades, facilities around the world have struggled to maintain consistent tertiary treatment performance using conventional granular media filters. These older systems often require larger footprints, higher maintenance, and greater energy input—making it difficult for plants to meet modern effluent targets or handle increasing hydraulic demands.

The AquaDisk® Cloth Media Filter changed that landscape. As the first disk-based cloth filtration system introduced to the market, AquaDisk® established a new benchmark for tertiary treatment efficiency. Today, it remains the most widely installed cloth media filter configuration globally, trusted for its exceptional performance, proven reliability, and long-standing operating history across both municipal and industrial applications.

Engineered with exclusive OptiFiber® filtration media and a compact, vertically oriented disk design, AquaDisk® delivers high-quality effluent, reduces phosphorus, and consistently produces reuse-grade water—making it one of the most dependable filtration solutions in the industry.

How It Works

AquaDisk® achieves continuous tertiary filtration through a simple, efficient, and highly reliable three-phase process. Using depth filtration and automatic cleaning, the system maintains stable operation even during peak flow events.

Filtration Mode

Wastewater flows by gravity into the filter basin, where the fully submerged cloth-media disks begin the filtration process. As water passes through the pile cloth depth:

- Suspended solids are trapped within the cloth fibers

- Clarified filtrate is collected through the hollow disk core

- Treated water exits over the effluent weir

- Heavy particles naturally settle to the tank bottom

This depth filtration ensures superior solids reduction and consistently high effluent clarity.

Backwash Mode

Automatic backwashing is triggered when headloss reaches a pre-set level:

- Disks rotate slowly during the cleaning cycle

- Backwash shoes contact the cloth surface directly

- Vacuum pressure lifts and removes stored solids

- Filtration continues uninterrupted

The low backwash rate and non-interruptive operation contribute to outstanding hydraulic efficiency.

Solids Handling

Settled solids accumulated at the tank bottom are periodically withdrawn and directed to the plant’s sludge-handling processes. This keeps the system hydraulically stable while preventing buildup and maintaining long-term performance.

Proven Features & Specifications

Application-Specific OptiFiber® Media

Multiple cloth media options are available to meet varying treatment goals—including phosphorus reduction and reuse-quality filtration.

Compact Vertical Disk Design

Vertically oriented disks significantly reduce footprint requirements while maintaining high filtration capacity.

Easy Maintenance

Each disk includes six lightweight, removable segments, allowing quick inspection and simplified service.

Flexible Construction Options

Available in painted steel, stainless steel, or concrete tanks to suit project requirements.

Multiple Acquisition Options

New, used, and rental units are available, offering cost-effective deployment for facilities with budget or time constraints.

Benefits That Matter

- Higher solids and hydraulic loading rates for increased throughput

- Low hydraulic profile, ideal for retrofit applications

- Low backwash rate, minimizing water loss and energy use

- Fully automated PLC control system with color touchscreen HMI

- Low life-cycle cost, driven by reduced maintenance and energy demand

AquaDisk® is engineered for real-world performance—delivering stable, predictable treatment results with minimum operator involvement and long-term reliability.

Upgrade Your Tertiary Treatment with AquaDisk®

Aging sand filters and high-maintenance media systems can limit your plant’s ability to meet future regulations. The AquaDisk® Cloth Media Filter offers a proven, efficient, and space-saving solution for achieving consistent effluent quality, enhanced reuse potential, and long-term operational savings.

Whether for municipal polishing, industrial wastewater treatment, or reuse applications, AquaDisk® delivers robust performance and sustainable operation.