AquaPrime® – The Next Generation Primary Treatment for Wastewater

Primary treatment is often the most challenging stage in a wastewater plant – high solids loads, fluctuating influent, and aging equipment commonly result in poor performance and higher downstream operational costs. Traditional clarification or screening solutions struggle to deliver consistent results, especially during peak or wet-weather flows.

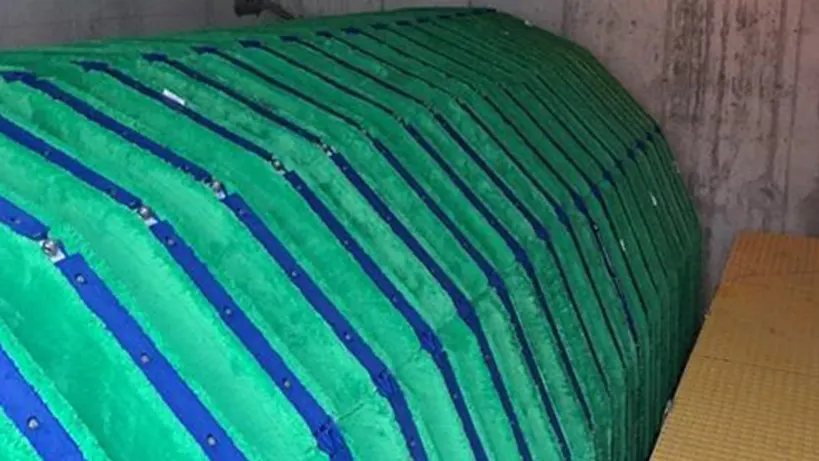

Our Partner, Aqua-Aerobic’s Cloth Media Filtration System is engineered to directly address these limitations. Using an advanced disk-based filtration design and high-performance pile-cloth media, it ensures superior solids capture, stable operation, and high-quality effluent without the use of chemicals. This makes it a reliable, energy-efficient, and future-ready solution for modern wastewater facilities.

How Does It Work?

The system operates through a smart; multi-stage filtration sequence designed for continuous performance – even under variable load conditions.

1. Efficient Filtration Mode

Wastewater flows into the system by gravity, where fully submerged cloth-media disks begin the filtration process. As water passes through the specialized pile cloth:

- Suspended solids accumulate on the outer surface, forming an effective filtration layer

- The tank level rises gradually as headloss develops

- Clean filtrate is collected through the hollow disk core and discharged over an effluent weir

- Heavy solids settle naturally into the hopper-shaped tank bottom.

This simple, robust filtration process delivers a consistently clear effluent while minimizing mechanical stress.

2. Reliable Backwash Mode

To maintain peak filtration performance, backwashing is triggered automatically – based on time or rising water level.

During backwash:

- Vacuum shoes make direct contact with the cloth media

- Trapped solids are gently lifted off the fibers using vacuum pressure

- Disks rotate slowly, allowing two disks to be cleaned at a time

- Filtration continues uninterrupted throughout the process

- Backwash water is transferred to the plant’s sludge-handling system.

This ensures the system remains clean, efficient, and fully online always.

3. Controlled Solids Wasting Mode

Settled heavy solids are periodically removed from the hopper:

- The backwash/solids pump draws accumulated sludge from the bottom

- Solids are directed to existing sludge-handling processes such as digesters or thickeners

This prevents buildup and keeps the filtration basin operating at optimal hydraulic conditions.

4. Floatable Wasting Mode

Floating scum naturally forms on the surface and is removed through a dedicated scum management cycle:

- After a set number of backwashes, water level is raised above the normal operating range

- The rise allows floating matter to pass over the scum-removal weir

- Removed scum is routed to the plant’s sludge treatment system

This maintains a clean operating surface and prevents odors or carryover.

Proven Features & Benefits

Compact, Efficient Design

Vertical cloth-media disks minimize footprint and offer easy access for inspection and maintenance.

High Solids Capture

Advanced OptiFiber-type pile cloth media greatly enhances removal of suspended solids and organic matter, reducing downstream load.

Low Maintenance Requirements

Lightweight segments, durable construction, and an efficient backwash system ensure long service life with minimal operator attention.

Energy-optimized Operation

Continuous filtration with minimal mechanical movement results in significantly lower energy usage compared to conventional primary treatment equipment.

Consistent Effluent Quality

Stable performance during variable or peak flow conditions ensures reliable clarity and supports stringent discharge requirements.

Automated, user-Friendly Control

A PLC-controlled system with touchscreen HMI offers complete automation, simplified control, and reliable unattended operation.

Why Facilities Trust AquaPrime® Cloth Media Filtration

Organizations choose this technology because it delivers measurable improvements across the treatment process:

Reduced Organic Load – Lower BOD/COD entering secondary treatment reduces energy consumption and improves biological stability.

Operational Efficiency – Automated operation and low maintenance minimize operator workload and downtime.

Higher Biogas Production – More solids captured during primary treatment increase potential digester output.

Regulatory Compliance – Superior solids removal supports consistent compliance with effluent norms.

Rapid ROI – Energy savings, reduced maintenance, and enhanced downstream performance accelerate payback.

Built for real-world performance, the AquaPrime® Cloth Media Filtration System supports municipal and industrial facilities looking for a dependable, sustainable alternative to conventional primary treatment.