AWA BioCell – Integrated Fixfilm Activated Sludge (IFAS) System

For Greenfield and Brownfield (upgradation) Wastewater Treatment Projects

Awatech presents the AWA BioCell, an innovative IFAS (Integrated Fixed-Film Activated Sludge) system designed for both new installations and upgradation of existing treatment plants. This next-generation solution combines the advantages of suspended growth and attached growth technologies to deliver enhanced biological performance and operational efficiency.

The system uses Fixed-Film Cage (FFC) bio-media, engineered to significantly enhance active biomass concentration within the aeration basin. By providing an extensive surface area for microbial attachment and growth, the FFC media sustains a high-density biological population, effectively increasing the Mixed Liquor Suspended Solids (MLSS) without expanding the physical reactor volume. This intensified biological environment boosts overall treatment capacity, improves process stability, and ensures consistent effluent quality under varying load conditions.

Depending on its placement within the reactor, the AWA BioCell facilitates aerobic, anoxic, and anaerobic conditions, ensuring optimal nutrient removal and complete biological purification. The result is a compact, energy-efficient, and high-performance wastewater treatment solution suitable for municipal, industrial, and decentralized systems.

Overview

The AWA BioCell IFAS System integrates attached growth technology with a modular reactor design to deliver highly efficient and reliable biological wastewater treatment. Built around Awatech’s proprietary Fixed-Film Cage (FFC) bio-media, the system ensures superior pollutant removal and process stability across diverse operating conditions.

Attached Growth Technology

The AWA BioCell employs engineered media that promote the colonization of beneficial microorganisms, forming an active biofilm layer. This biofilm efficiently breaks down organic pollutants while supporting nitrification, denitrification, and phosphorus removal. By maintaining distinct microbial zones within the reactor, the system achieves advanced biological nutrient removal in a compact footprint.

Modular FFC Media

The lightweight, stackable cage-type FFC modules maximize contact between wastewater and biofilm surface. This design significantly increases the effective biomass concentration without raising suspended solids in the system. Continuous aeration ensures optimal oxygen transfer and natural scouring, preventing excess biofilm buildup and maintaining consistent treatment performance.

Efficient Operation

With no moving parts in the media itself, the AWA BioCell offers a simple yet robust configuration. Its stationary design minimizes internal recirculation, reduces energy consumption, and makes both installation and maintenance easy and cost-effective. The result is a dependable, long-lasting solution ideal for both greenfield and brownfield wastewater projects.

Key Benefits

Increases Plant Capacity & Efficiency

By integrating fixed-film bio-media within existing basins, the AWA BioCell significantly increases biomass concentration and treatment efficiency. It enables the creation of parallel treatment zones – aerobic, anoxic and anaerobic – within a single reactor, effectively boosting plant capacity without requiring additional civil infrastructure.

Improved Solids Settleability

The system enhances sludge characteristics, resulting in a lower Sludge Volume Index (SVI) and better suspended solids settling. This improvement leads to clearer effluent, more stable sludge management, and reduced carryover from secondary clarifiers compared to conventional activated sludge systems.

High Nutrient Removal

The AWA BioCell consistently achieves ammonia level below 5mg/L, while maintaining BOD, COD, and TSS in the treated effluent within the range of 8-10 mg/L. The result is superior effluent quality that easily complies with stringent discharge standards and regulatory norms.

Odor & Greenhouse Gas Control

Through optimized biological conditions and improved oxygen transfer, the system minimizes the generation of methane and other odorous compounds, ensuring a cleaner, more sustainable treatment environment.

Prevention of Eutrophication

By effectively removing nitrogen and phosphorus, the AWA BioCell helps in prevention of eutrophication in receiving water bodies such as lakes and reservoirs. This ensures environmentally safe discharge and supports aquatic ecosystem health.

How the AWA BioCell FFC Media System Works

Optimized Biofilm Dynamics

The system maintains the controlled biofilm thickness, allowing for efficient oxygen transfer and effective nutrient uptake by the attached microorganisms. This stable biofilm environment supports robust biological activity, enabling rapid breakdown of organic pollutants and efficient removal of nitrogen and phosphorus.

Continuous Self-Cleaning Action

A unique self-scouring mechanism prevents excess biofilm buildup on the media surface. The gentle but continuous hydraulic movement keeps the biofilm at its most effective thickness – ensuring long-term operational stability and maintaining high treatment efficiency without manual intervention.

Reliable, Low-Maintenance Operation

With no moving parts, mechanical screens, or complex internals, the AWA BioCell minimizes the risk of mechanical failure and reduces maintenance demands. This simplicity translates into lower operational costs and extended system longevity, even under variable load conditions.

Simplified Installation & Intelligent Flow Design

The lightweight, modular bio-media and support assemblies are designed for easy installation in both new and existing treatment tanks. Within the basin, the media cage towers are strategically arranged to create a plug-flow hydraulic pattern, promoting uniform treatment and eliminating the need for traditional baffles. This efficient configuration enhances contact time, reduces dead zones, and improves overall system performance.

Performance Highlights

Reliable Operation in Variable Conditions

Engineered to maintain biological activity even under low temperatures and fluctuating pH levels, the AWA BioCell delivers reliable performance across diverse climates and wastewater characteristics. The resilience makes it particularly effective for industrial and municipal plants facing variable influent loads or seasonal temperature shifts.

High Surface Area for Enhanced Treatment Efficiency

Each bio-media unit provides a specific surface area of 278 m2/m3, creating ample space for microbial attachment and biofilm development. This high surface density enables the system to handle up to 0.8 kg NH4-N per 1000 m2 per day, ensuring excellent ammonia oxidation and nutrient removal rates within a compact footprint.

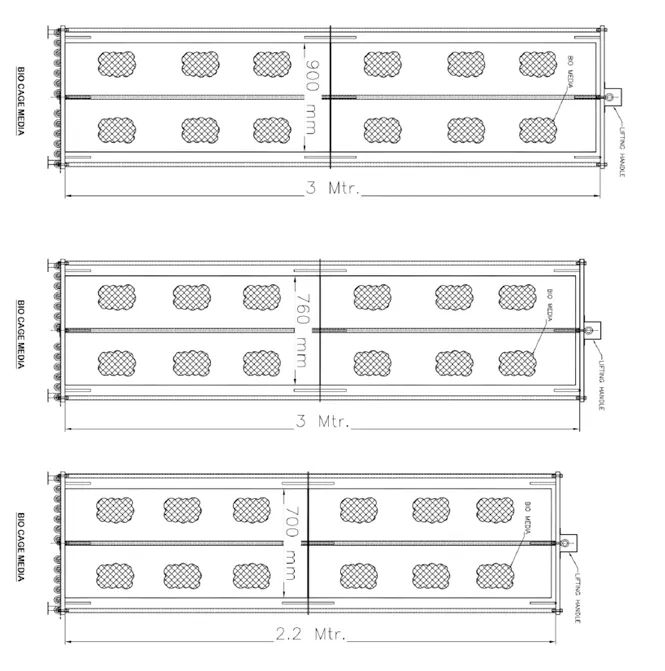

AWA BioCell models

| Model | Dia (mm) | Height (M) | SWD (M) | Suspended Solids (mg/L) |

|---|---|---|---|---|

| ABC 9003 | 900 | 3.0 | 4.5 | 6000-7000 |

| ABC 7603 | 760 | 3.0 | 4.5 | 6000-7000 |

| ABC 70022 | 700 | 2.2 | 2.5 | 6000-7000 |

Sketch of models

Aqua MSBR® - Modified Sequencing batch Reactor

Next-generation Continuous Biological Treatment for Large Municipal & Industrial Plants

Large-scale wastewater treatment facilities face increasing challenges – higher flows, strict nutrient limits, stricter nutrient limits, space constraints, and the need for stable year-round operation. Traditional SBRs often struggle to handle continuous inflow, while conventional flow-through activated sludge systems require large footprints and multiple structures to achieve advanced nutrient removal.

The Aqua MSBR® (Modified Sequencing Batch Reactor) overcomes these limitations by merging the strengths of SBR technology with the reliability of a continuous flow activated sludge process. The result is a compact, high-performance, cost-effective biological treatment system designed for capacities >15,000 m3/day.

Aqua MSBR provides exceptional nutrient removal, stable hydraulic operation, and simplified process control – making it ideal for large municipal STPs and demanding industrial applications.

How It Works

Aqua MSBR® operates using a time-based, four-phase biological treatment cycle, delivering predictable and efficient removal of carbon, nitrogen, and phosphorus.

Four Phases of Operation

Anoxic Mixing & Mixed Liquor Recycle

Denitrification begins as nitrate-rich mixed liquor is circulated under anoxic conditions.

Aeration, Mixing & Mixed Liquor Recycle

Aerobic conditions promote carbon oxidation and nitrification, while internal recycle stabilizes biomass activity.

Pre-Settle

Mixing and aeration pause; solids begin to settle in preparation for final clarification.

Clarification

A quiescent environment is created, allowing high-quality treated water to be withdrawn with minimal TSS.

These phases occur continuously across the system, ensuring no interruption to plant influent flow.

Inside the 7-Cell System Design

Aqua MSBR® uses a strategic multi-cell configuration to achieve advanced biological nutrient removal:

Cells 1 & 7 – Sequencing Cells

These two cells alternate all four treatment phases. When Cell 1 is progressing through phases 1-3, Cell 7 remains in clarification – and vice versa – supporting continuous flow and discharge.

Cell 2 – Phase Separator Cell

Concentrates mixed liquor solids and promotes favorable conditions for phosphorus release in the downstream anaerobic zone.

Cell 3 – Fermentation Cell

Generates and enriches volatile fatty acids (VFAs), essential for enhanced biological phosphorus removal.

Cell 4 – Anaerobic cell

Provides optimized anaerobic conditions to promote phosphorus release from PAOs (phosphorus accumulating organisms).

Cell 5 – Anoxic Mixing cell

Dedicated to denitrification, reducing nitrate levels efficiently.

Cell 6 – Aerobic Cell

Provides oxidation of carbonaceous BOD, nitrification, and biological phosphorus uptake.

This structured hydraulic progression ensures stability, predictability, and superior nutrient removal even under challenging influent conditions.

Features & Specifications

Continuous Flow, constant Level Operation

Eliminates the intermittent hydraulics of conventional SBRs.

Simple, Robust Operation

Time-Based Activated Sludge design minimizes operator intervention.

Handles Peak Flows

Designed to accommodate large hydraulic surges during storm events.

Quiescent Settling & High-Quality Clarification

Enhances solids separation and minimizes TSS carryover.

Optimized Nutrient Removal

Excellent performance in EBPR, nitrification, and denitrification.

Flexible Infrastructure

- No separate clarifier basins required

- Existing aeration systems can be integrated

- Ideal for greenfield or retrofit applications

Benefits That Matter

- Compact system footprint with no need for separate structures

- Stable performance in low-strength, low-temperature wastewater

- Fully automated PLC control, ensuring reliable phase transitions

- Improved sludge flocculation without mechanical sludge collection devices

- Low effluent, TSS supporting stringent discharge norms

- Enhanced BNR performance with effective phosphorus, nitrogen, and BOD removal

- Lower capital and operating cost compared to conventional flow-through systems

- Optimized basin configuration for process stability and hydraulic efficiency

Aqua MSBR® is engineered to deliver consistent biological performance – even under variable loads, extreme temperatures, and challenging influent characteristics.

Upgrade to the Aqua MSBR® Advantage

Large municipal and industrial wastewater facilities demand reliability, efficiency, and flexibility. The Aqua MSBR® system provides all of these benefits in a single, integrated continuous-flow process.

If you’re looking to improve nutrient removal, reduce footprint, modernize existing infrastructure, or design a high-capacity biological system – the aqua MSBR delivers a proven path forward.

AWA i-SBR: An intelligent Sequencing Batch Reactor Process for Wastewater Treatment with Biological Nutrient Removal Capability

Next-generation Continuous Biological Treatment for Large Municipal & Industrial Plants

The AWA i-SBR represents the next generation of biological wastewater treatment systems, combining the proven performance of the Sequencing Batch Reactor (SBR) process with advanced automation and nutrient removal capability.

Unlike conventional activated sludge systems that rely on multiple tanks and complex piping arrangements to achieve different treatment stages, the AWA i-SBR performs the entire treatment cycle within a single reactor. This smart, time-sequenced process integrates all phases of treatment-fill, react, settle, decant, and idle – in one chamber, ensuring operational simplicity, compact design, and superior effluent quality.

Modern wastewater treatment demands precise control of aerobic, anoxic, anaerobic, and quiescent environments to effectively remove suspended solids and nutrients such as nitrogen and phosphorus. The AWA i-SBR intelligently creates and manages these conditions sequentially within the same reactor, optimizing biological activity for consistent, high-quality performance.

Because treatment occurs in controlled batches of fixed volume, the process provides exceptional flexibility in operation, control, and scalability. Each cycle is automatically adjusted to match influent characteristics, ensuring stable treatment efficiency and regulatory compliance even under variable load conditions.

Key Equipment Used in SBR Operation

- Influent gate or Valves: Regulate the controlled entry of wastewater into the reactor, allowing accurate batch volume management and maintaining the designed hydraulic retention time.

- Aeration System: Supplies oxygen during the aerobic phase to support biological oxidation and nitrification, ensuring effective removal of organic matter and ammonia.

- Mixing Devices: Maintain uniform conditions during anaerobic and anoxic phases, facilitating efficient denitrification and biological phosphorus removal.

- Excess Sludge Pumps: Periodically removes surplus biomass generated during treatment, keeping the microbial population balanced and preventing process overload.

- Effluent Gates or Valves: Discharge treated water during the decant phase, ensuring high-clarity effluent while preventing floating solids from escaping the reactor.

The complete wastewater treatment process in the AWA i-SBR is executed through five sequential phases, each designed to create specific biological and hydraulic conditions for optimal contaminant and nutrient removal.

Phase 1: Filling & Mixing Phase

The filling and mixing phase marks the beginning of the AWA i-SBR treatment cycle, where raw wastewater is introduced into the reactor and prepared for biological processing. During this stage, influent flow is carefully regulated, and intermittent mixing is initiated to achieve uniform distribution without aeration.

- The reactor is filled with wastewater, and the mixers operate intermittently. The AWA i-SBR employs mixers, specifically designed to provide efficient mixing without the introduction of oxygen.

- This creates controlled anaerobic environment as dissolved oxygen is rapidly consumed, and nitrate levels are depleted.

- In this state, the static fill conditions facilitate an environment where phosphate accumulating organisms (PAO) become dominant. This process is a critical stage in biological phosphorus removal, setting the foundation for efficient nutrient elimination in the subsequent treatment phases.

Phase 2: Filling & Aeration Phase

- In this stage, the reactor continues to fill while aeration and mixing operate intermittently, maintaining balanced biological conditions. By regulating the duration of aeration during filling, the AWA i-SBR allows precise control over substrate availability, helping to manage filamentous organisms and nitrogen concentrations effectively.

- This phase alternates between anaerobic, anoxic and aerobic conditions, promoting both organic oxidation and nutrient removal. While the anaerobic intervals enhance phosphorus release and uptake, the aerobic periods facilitate ammonia oxidation to nitrates.

- The integration of anaerobic, anoxic, and aerobic environments within a single treatment phase through time-controlled equipment represents a distinctive feature of the AWA i-SBR system.

Phase 3: Aeration Phase

- In this phase, filling is halted using influent gates or valves, thereby establishing a true batch process.

- In this phase, intensive aeration promotes biological oxidation, supporting the breakdown of remaining organic matter and nutrient compounds.

- Intermittent mixing ensures even air distribution and consistent contact between microorganisms and the wastewater.

- This stage completes the reactions initiated earlier, focusing on BOD reduction, nitrification, and nutrient polishing.

- Serving as an additional treatment barrier, this phase ensures comprehensive polishing of wastewater prior to settling and final discharge.

Phase 4: Settling/Idle

All equipment will be turned off in this phase to create a quiescent environment, enabling heavy solids from the Aeration phase to settle.

Phase 5: Decant & Sludge Transfer

- During this final phase, clarified effluent is gently withdrawn from the top of the reactor while the settled solids remain undisturbed at the bottom.

- The AWA i-SBR incorporates an advanced decanting system with a baffle and floating mechanism that automatically follows the water level, enabling subsurface decantation and preventing floating debris from entering downstream units.

- At set intervals, excess sludge is removed using pumps or weirs to maintain the optimal concentration of active biosolids within the reactor. This ensures stable biological performance, consistent effluent quality, and long-term system efficiency.

AWA i-SBR’s data-driven, time-controlled, and adaptive operating system provides process control by considering dynamic flow and influent parameters to support process optimization and energy efficiency while maintaining effluent quality. The AWA i-SBR system monitors indirect parameters online, such as pH, dissolved oxygen, oxidation-reduction potential, and NH4-N, which assists in identifying the timing of carbon and nitrogen removal for process optimization.

Unique Features

- True Batch Process: All treatment stages – filling, aeration, mixing, and decanting – occur in single reactor, minimizing footprint, civil construction, and operational complexity while achieving superior nutrient and phosphorus removal.

- Operational Flexibility: Advanced monitoring and control systems enable smooth operation despite changes in sewage flow.

- Smart Optimization: The intelligent control system eliminates the need for Return Activated Sludge (RAS) recycling, maximizing energy efficiency and reducing the need for manual intervention.

- Life Cycle: A robust, streamlined design with high-quality, easily accessible components ensures long-term reliability, simplified maintenance, and reduced life cycle costs.